Wood Chip Tumbling

Each frame is placed into a rotating wooden barrel filled with fine wood chips and polishing compound. Over several hours, this process softens sharp edges and begins developing the natural luster of the acetate. It’s the first step toward achieving the deep, rich finish associated with handcrafted eyewear.

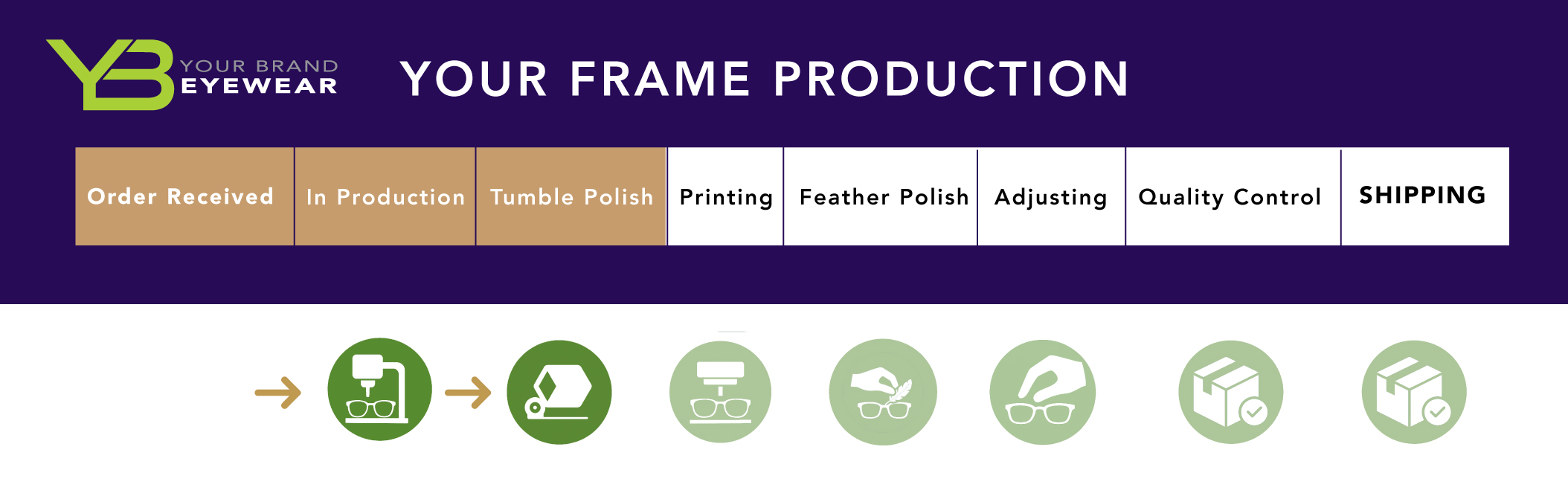

What’s Next:

Once the rough tumbling stage is complete, your frames move to Printing, where your logos and branding are added.